Heavy Duty Hoist Rings

Heavy Duty Hoist Rings

Material: 4140 High Strength Alloy Steel / Heat treated to 180,000 p.s.i.

Finish: Black Oxide

• Range of movement: Pivot 180°, swivel 360°

• MINIMUM SAFETY FACTOR=5:1

• Meets Military Specification No. MIL-STD 1365(11) or MIL-STD 209C

• Heavy Duty Hoist Rings are specified and used in Nuclear Energy Equipment.

• 100% Magnetic Particle Inspected

• Meets OSHA Standards

• Destructive testing by outside independent laboratories

• OVER 30 YEARS OF RELIABILITY

• World's largest inventory. Over 95% of standards shipped in one day from stock.

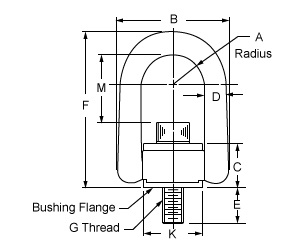

| Part No. | Rated Load (LBS.) | A | B | C | D | E | F | G | K | * TL Ft -LBS. | M | Weight (LBS.) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 833112 | 550 | 0.65 | 2.29 | 0.96 | 0.44 | 0.56 | 3.23 | 1/4-20 | 1.25 | 5 | 1.57 | 0.50 |

| 833212 | 800 | 0.65 | 2.29 | 0.96 | 0.44 | 0.56 | 3.23 | 5/16-18 | 1.25 | 7 | 1.51 | 0.52 |

| 833214 | 800 | 0.65 | 2.29 | 0.96 | 0.44 | 1.06 | 3.23 | 5/16-18 | 1.25 | 7 | 1.51 | 0.54 |

| 833312 | 1,000 | 0.65 | 2.29 | 0.96 | 0.44 | 0.56 | 3.23 | 3/8-16 | 1.25 | 12 | 1.45 | 0.56 |

| 833314 | 1,000 | 0.65 | 2.29 | 0.96 | 0.44 | 1.06 | 3.23 | 3/8-16 | 1.25 | 12 | 1.45 | 0.58 |

| 833512 | 2,500 | 1.00 | 3.50 | 1.50 | 0.75 | 0.75 | 5.31 | 1/2-13 | 1.89 | 28 | 2.56 | 1.71 |

| 833515 | 2,500 | 1.00 | 3.50 | 1.50 | 0.75 | 1.00 | 5.31 | 1/2-13 | 1.89 | 28 | 2.56 | 1.72 |

| 833516 | 2,500 | 1.00 | 3.50 | 1.50 | 0.75 | 1.25 | 5.31 | 1/2-13 | 1.89 | 28 | 2.56 | 1.82 |

| 833612 | 4,000 | 1.00 | 3.50 | 1.50 | 0.75 | 0.75 | 5.31 | 5/8-11 | 1.89 | 60 | 2.44 | 1.76 |

| 833614 | 4,000 | 1.00 | 3.50 | 1.50 | 0.75 | 1.00 | 5.31 | 5/8-11 | 1.89 | 60 | 2.44 | 1.78 |

| 833615 | 4,000 | 1.00 | 3.50 | 1.50 | 0.75 | 1.25 | 5.31 | 5/8-11 | 1.89 | 60 | 2.44 | 1.88 |

| 833714 | 5,000 | 1.00 | 3.50 | 1.50 | 0.75 | 1.00 | 5.31 | 3/4-10 | 1.89 | 100 | 2.31 | 1.89 |

| 833716 | 5,000 | 1.00 | 3.50 | 1.50 | 0.75 | 1.25 | 5.31 | 3/4-10 | 1.89 | 100 | 2.31 | 2.02 |

| 833108 | 7,000 | 1.40 | 5.10 | 2.05 | 1.00 | 0.95 | 7.00 | 3/4-10 | 2.81 | 100 | 3.20 | 7.20 |

| 833102 | 7,000 | 1.40 | 5.10 | 2.05 | 1.00 | 1.20 | 7.00 | 3/4-10 | 2.81 | 100 | 3.20 | 7.23 |

| 833103 | 7,000 | 1.40 | 5.10 | 2.05 | 1.00 | 1.45 | 7.00 | 3/4-10 | 2.81 | 100 | 3.20 | 7.25 |

| 833104 | 8,000 | 1.40 | 5.10 | 2.05 | 1.00 | 0.95 | 7.00 | 7/8-9 | 2.81 | 160 | 3.07 | 7.33 |

| 833101 | 8,000 | 1.40 | 5.10 | 2.05 | 1.00 | 1.20 | 7.00 | 7/8-9 | 2.81 | 160 | 3.07 | 7.33 |

| 833105 | 10,000 | 1.40 | 5.10 | 2.05 | 1.00 | 1.45 | 7.00 | 1-8 | 2.81 | 230 | 2.95 | 7.57 |

| 833106 | 10,000 | 1.40 | 5.10 | 2.05 | 1.00 | 1.20 | 7.00 | 1-8 | 2.81 | 230 | 2.95 | 7.63 |

| 833107 | 10,000 | 1.40 | 5.10 | 2.05 | 1.00 | 2.20 | 7.00 | 1-8 | 2.81 | 230 | 2.95 | 7.81 |

| 833402 | 15,000 | 2.00 | 6.75 | 2.87 | 1.25 | 1.88 | 9.22 | 1 1/4 - 7 | 3.88 | 470 | 3.74 | 15.74 |

| 833401 | 15,000 | 2.00 | 6.75 | 2.87 | 1.25 | 2.63 | 9.22 | 1 1/4 - 7 | 3.88 | 470 | 3.74 | 16.0 |

| 833420 | 20,000 | 2.00 | 6.75 | 2.87 | 1.25 | 2.63 | 9.22 | 1 3/8 - 6 | 3.88 | 670 | 3.62 | 17.2 |

| 833424 | 24,000 | 2.00 | 6.75 | 2.87 | 1.25 | 2.63 | 9.22 | 1 1/2 - 6 | 3.88 | 800 | 3.49 | 18.1 |

| 833427 | 30,000 | 2.00 | 6.75 | 2.87 | 1.25 | 2.96 | 9.22 | 2 - 4 1/2 | 3.88 | 800 | 3.49 | 22.9 |

| 833432 | 30,000 | 2.00 | 6.75 | 2.87 | 1.25 | 2.96 | 9.22 | 2-8 | 3.88 | 800 | 3.49 | 22.9 |

* Recommended Torque Load

| Part No. | Rated Load (KG) | A | B | C | D | E | F | G | K | * TL N.M. | M | Weight (KG) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 834212 | 400 | 16.5 | 58.2 | 24.4 | 11.1 | 16 | 82.0 | M8 x 1.25 | 31.8 | 9.5 | 38.5 | 0.11 |

| 834214 | 400 | 16.5 | 58.2 | 24.4 | 11.1 | 21 | 82.0 | M8 x 1.25 | 31.8 | 9.5 | 38.5 | 0.11 |

| 834312 | 450 | 16.5 | 58.2 | 24.4 | 11.1 | 16 | 82.0 | M10 x 1.5 | 31.8 | 16.0 | 36.5 | 0.11 |

| 834314 | 450 | 16.5 | 58.2 | 24.4 | 11.1 | 26 | 82.0 | M10 x 1.5 | 31.8 | 16.0 | 36.5 | 0.12 |

| 834515 | 1,050 | 25.4 | 88.9 | 38.1 | 19.1 | 25 | 134.9 | M12 x 1.75 | 48.0 | 37.0 | 65.0 | 0.35 |

| 834516 | 1,050 | 25.4 | 88.9 | 38.1 | 19.1 | 32 | 134.9 | M12 x 1.75 | 48.0 | 37.0 | 65.0 | 0.38 |

| 834614 | 1,900 | 25.4 | 88.9 | 38.1 | 19.1 | 25 | 134.9 | M16 x 2.0 | 48.0 | 80.0 | 62.0 | 0.37 |

| 834615 | 1,900 | 25.4 | 88.9 | 38.1 | 19.1 | 32 | 134.9 | M16 x 2.0 | 48.0 | 80.0 | 62.0 | 0.39 |

| 834714 | 2,200 | 25.4 | 88.9 | 38.1 | 19.1 | 25 | 134.9 | M20 x 2.5 | 48.0 | 135.0 | 58.7 | 0.39 |

| 834716 | 2,200 | 25.4 | 88.9 | 38.1 | 19.1 | 38 | 134.9 | M20 x 2.5 | 48.0 | 135.0 | 58.7 | 0.42 |

| 834101 | 3,000 | 35.6 | 129.5 | 52.1 | 25.4 | 28 | 177.8 | M20 x 2.5 | 71.4 | 135.0 | 81.0 | 1.42 |

| 834102 | 4,200 | 35.6 | 129.5 | 52.1 | 25.4 | 28 | 177.8 | M24 x 3.0 | 71.4 | 311.0 | 76.3 | 1.49 |

| 834103 | 4,200 | 35.6 | 129.5 | 52.1 | 25.4 | 38 | 177.8 | M24 x 3.0 | 71.4 | 311.0 | 76.3 | 1.50 |

| 834105 | 4,500 | 35.6 | 129.5 | 52.1 | 25.4 | 38 | 177.8 | M30 x 3.5 | 71.4 | 311.0 | 70.3 | 1.56 |

| 834107 | 4,500 | 35.6 | 129.5 | 52.1 | 25.4 | 48 | 177.8 | M30 x 3.5 | 71.4 | 311.0 | 70.3 | 1.61 |

| 834401 | 7,000 | 50.8 | 171.5 | 72.9 | 31.8 | 67 | 234.2 | M30 x 3.5 | 73.2 | 637.2 | 95.0 | 3.29 |

| 834402 | 11,000 | 50.8 | 171.5 | 72.9 | 31.8 | 67 | 234.2 | M36 x 4.0 | 73.2 | 1,085.5 | 88.6 | 3.72 |

| 834403 | 12,500 | 50.8 | 171.5 | 72.9 | 31.8 | 80 | 234.2 | M42 x 4.5 | 73.2 | 1,085.5 | 88.6 | 4.60 |

| 834404 | 13,500 | 50.8 | 171.5 | 72.9 | 31.8 | 80 | 234.2 | M48 x 5.0 | 73.2 | 1,085.5 | 88.6 | 4.80 |

Unit: mm

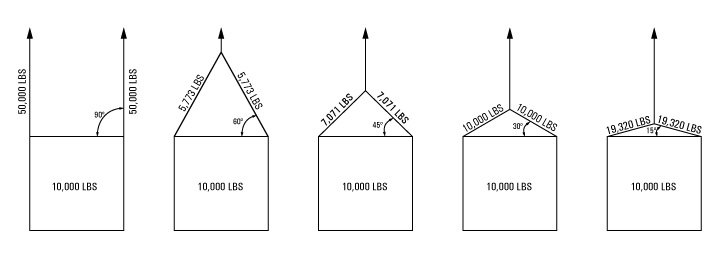

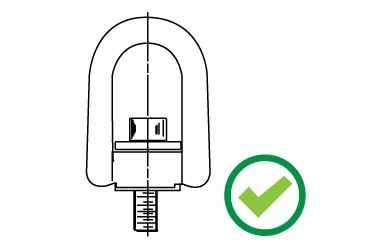

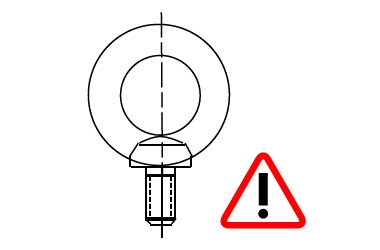

Use Hoist Rings for added lifting safety

Side or angular pulling forces can cause eyebolts to twist, bend, or break when heavy, angular, unbalanced loads are involved.

| HeavyDutyHoist Rings | |||

|---|---|---|---|

| Thread Size | Rated Load Capacity / LBS. | ||

| Straight Pull | 45º Lift | 90º Lift | |

| 1/4-20 | 550 | 550 | 550 |

| 5/16-18 | 800 | 800 | 800 |

| 3/8-16 | 1,000 | 1,000 | 1,000 |

| 1/2-13 | 2,500 | 2,500 | 2,500 |

| 5/8-11 | 4,000 | 4,000 | 4,000 |

| 3/4-10 | 5,000 | 5,000 | 5,000 |

| 7/8-9 | 8,000 | 8,000 | 8,000 |

| 1-8 | 10,000 | 10,000 | 10,000 |

| 1 1/4 - 7 | 15,000 | 15,000 | 15,000 |

| 1 1/2-6 | 24,000 | 24,000 | 24,000 |

| Shoulder Eyebolts | |||

|---|---|---|---|

| Thread Size | Rated Load Capacity / LBS. | ||

| Straight Pull | 45º Lift | 90º Lift | |

| 1/4-20 | 480 | 144 | 120 |

| 5/16-18 | 800 | 240 | 200 |

| 3/8-16 | 1,200 | 360 | 300 |

| 1/2-13 | 2,200 | 660 | 550 |

| 5/8-11 | 3,500 | 1,050 | 875 |

| 3/4-10 | 5,200 | 1,560 | 1,300 |

| 7/8-9 | 7,200 | 2,160 | 1,800 |

| 1-8 | 10,000 | 3,000 | 2,500 |

| 1 1/4 - 7 | 15,200 | 4,560 | 3,800 |

| 1 1/2-6 | 21,400 | 6,420 | 5,350 |